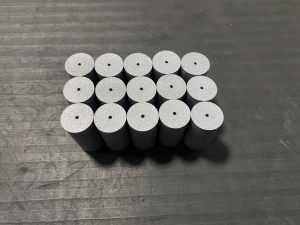

Fastener Industry Lo Tungsten Carbide Cold Forging Die

1. Chinese factory specialized ni processing ati gbóògì, ISO iwe eri.

2. Awọn titobi pupọ ati awọn iru ti o wa fun OEM.

3. Ṣe ti 100% atilẹba awọn ohun elo ti o ga julọ

4. Ẹgbẹ iṣelọpọ ọjọgbọn, ifijiṣẹ yarayara

5. Free ọjọgbọn lẹhin-tita iṣẹ ati imọ support

Tungsten carbide tutu awọn akọle ku ni a lo pupọ fun ṣiṣe mimu simẹnti ipari ti o pari, Punch ku, iyaworan okun waya, ẹrọ mimu, iku ilọsiwaju, ku extrusion, tẹ m, awọn ẹya mimu, gige gige, akọle tutu ku, mimu eke, tutu dagba ku ati be be lo.

| Tungsten Carbide Cold Forging / akori Dies | |||||

| Awọn ipele | iwuwo | TRS | Lile | Iṣe & elo niyanju | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Dida tabi stamping ku fun irin powders ati nonmetal powders. | |

| YG15 | 14 | ≥3400 | 87.5 | Fun sisọ iyaworan ku ti awọn tubes irin ati awọn ọpa labẹ ipin compressibility giga;punching, stamping, ayederu irinṣẹ labẹ tobi wahala. | |

| YG20 | 13.5 | ≥3800 | 85.5 | Fun sisẹ ti stamping ku fun awọn ẹya aago, awọn awo orisun omi ti awọn ohun elo orin, awọn pọn batiri, awọn bọọlu irin kekere, awọn skru, awọn bọtini dabaru. | |

| YG15C | 14 | ≥4000 | 86.5 | Fun awọn gige lilu konu epo, ge alabọde rirọ ati awọn apata lile; debarking ati gige igi tio tutunini, igi rirọ ati igi atilẹba. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Ipa resistance forging ku. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Ikolu resistance forging kú, gbona-tẹ forging kú ati rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Ku fun yiya sooro tabi ikolu sooro ohun elo. | |

| YG22C | 13.3 | ≥4000 | 83 | Eso lara kú ati ki o ga ikolu resistance forging kú. | |

| YG25C | 13.1 | ≥4250 | 82.5 | Alagbara boluti akọsori kú ati rollers. | |

Ibamu ohun elo → Milling Ball tutu → Adalu WC ati Agbara koluboti → Titẹ → HIP Sintering Furnaces → Wiwa QC → Iṣakojọpọ

| Iru | OD | ID | H | Ifarada | ||

| OD | Id | H | ||||

| φD10~14×φd | 10-14 | 1.0-5.0 | 15-40 | D×+3% | d×-3% | H×+3% |

| φD15~24×φd | 15–24 | 1.5-8.0 | 20-60 | |||

| φD25~40×φd | 25-40 | 1.5-25 | 30-60 | |||

| φD42~95×φd | 42-95 | 2.0-50 | 20-95 | |||

Fun eyikeyi awọn iwọn miiran a ni anfani lati ṣe aṣa ni ibamu si awọn ibeere awọn alabara tabi awọn iyaworan.

1. A yoo gbiyanju gbogbo wa lati dahun ibeere awọn onibara wa laarin awọn wakati 24.

2. A yoo ṣetọju awọn ibaraẹnisọrọ to munadoko ati lilo daradara pẹlu awọn onibara wa.

3. A pese iṣakoso didara akọkọ-akọkọ ati awọn iṣẹ lẹhin-tita.

A yoo firanṣẹ ẹru ti a ṣejade laarin awọn ọjọ 30 lẹhin isanwo isalẹ, lakoko ti, Ti awọn ibeere soecific ba wa ni akoko ifijiṣẹ.A le ṣe iyipada ni ibamu si ibeere awọn alabara, nitorinaa akoko ifijiṣẹ kukuru kan wa patapata.

Nigbagbogbo 30% T / T ni ilosiwaju, iwọntunwọnsi 70% ṣaaju ifijiṣẹ.O tun le yipada ni ibamu si ibeere awọn alabara.

A ṣe awọn paati ni awọn nitobi ati awọn titobi oriṣiriṣi lati baamu awọn ibeere awọn alabara wa ni deede, boya wọn nilo awọn bulọọki tabi awọn iwe, awọn silinda, awọn bearings, awọn imọran tabi awọn eyin.