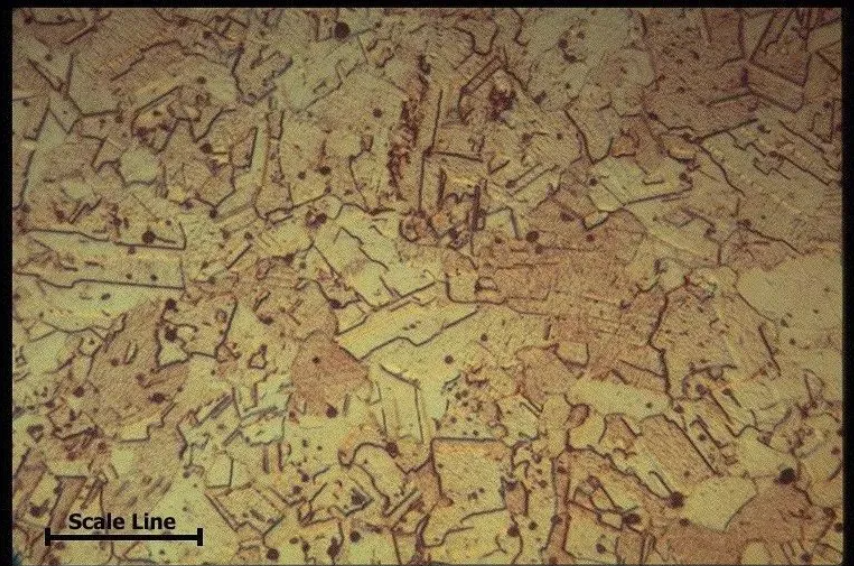

Tungsten carbidepores ti wa ni gbogbo ṣẹlẹ nipasẹ awọn impurities ninu awọn òfo Àkọsílẹ ṣaaju ki o to sintering.Nitori pinpin aiṣedeede ti awọn pores ninu apẹẹrẹ, awọn aaye diẹ diẹ sii yẹ ki o ṣe akiyesi.Nigbati o ba n ṣawari, o le ṣe akiyesi ọkan nipasẹ ọkan (lati eti apakan ayẹwo si aarin).Yan aaye wiwo julọ pẹlu awọn pores pupọ julọ ni akawe pẹlu aworan boṣewa porosity GB/T 3489-1983.GB/T3489-1983 aworan ìyí pore ti pin si awọn ipele 11, ati pe awọn pores rẹ jẹ iroyin fun 0.1%, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, 1.2%, 1.4%,

Tungstenawọn bulọọki carbidelẹhin polishing awọn ayẹwo ti wa ni woye ni 100 igba, ati awọn iwọn jẹ tobi ju tabi dogba si 25 μm.Awọn dudu iho pẹlu alaibamu ni nitobi sugbon ko o egbegbe ni a npe ni dọti.O ti wa ni eruku tabi awọn miiran idoti ti awọn eniyan ni adalutungsten carbidelulú ati ilana idinku, ati awọn iho idinku ti o fi silẹ nipasẹ idinku lẹhin sisọ.Awọn lapapọ ipari ti gbogbo idoti lori awọn ayẹwo dada polishing ni a npe ni dọti.

Akoko ifiweranṣẹ: Jan-14-2024